What are the types of containers used in maritime transport?

Shipping containers are one of the core foundations of modern international freight logistics. Although they may look similar from the outside, their structure, purpose, and internal dimensions can vary significantly. This wide range of container types results from the need to adapt to specific transportation requirements for different kinds of goods in ocean freight.

Choosing the right type of container is crucial for transport safety, cost-efficiency, operational effectiveness, and customs compliance. In this article, we present the most important types of containers used in maritime shipping, including their use cases, benefits, and key design features that directly affect the quality and efficiency of cargo transportation.

Why are there so many types of containers in maritime shipping?

In maritime and intermodal transport, nothing is left to chance. Every cargo type, transit time, and environmental condition requires a tailored logistics solution. That’s why professional freight companies offer a wide range of container products tailored to specific market and technical requirements.

It’s also important to note that not all containers used in sea freight are technically classified as maritime containers. Officially, a maritime container is one that meets ISO standards, has a valid CSC (Container Safety Convention) certificate, and is suitable for stacking and intermodal use aboard vessels. In practice, however, you’ll also find special-purpose containers used at sea that may not fully meet these standards but are still utilized in shipping operations.

What’s more, even within a single container group—like Flat Rack or Open Top — there can be models that meet full maritime requirements and others designed exclusively for land transport (e.g., road freight) or storage container use. It’s essential to consider both the container type and its specific technical features and purpose when planning any shipment.

Due to the diverse requirements of different cargo types, many types of containers are used in maritime transport. Some goods need to be shipped at a constant temperature, others are too long or tall to fit inside a standard container. Certain loads require top loading, side access, or special securing mechanisms. For each of these cases, there is a dedicated container type specifically designed for the task.

A well-chosen shipping container that meets the specific transport needs not only ensures proper cargo protection but also speeds up container handling at transshipment points and helps reduce transportation costs. All of this ensures that goods reach their destination in optimal conditions.

Standard Containers (Dry Vans, DV)

Standard containers, also known as Dry Vans (DV), are the most commonly used solution in maritime transport. Thanks to their universal application, they form the backbone of global trade. They are used to transport a wide variety of goods that do not require special temperature control or structural conditions.

Their construction is simple and enclosed — protecting the cargo from weather conditions and mechanical damage during transit. Dry Vans are widely used for transporting general cargo, palletized goods, and items such as household appliances, electronics, clothing, textiles, and industrial components.

Because of their standardized dimensions, they simplify transshipment at different stages of the journey — between ship, truck, or train. They are the foundation of intermodal transport, and their presence in nearly every port worldwide makes them the most accessible type of container. The most common sizes of Dry Van containers are 20′ and 40′.

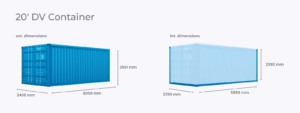

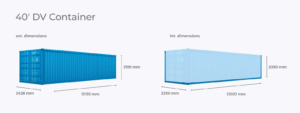

20′ DV and 40′ DV Containers

The 20-foot container is a classic in its category. Due to its relatively compact size, it is often chosen for transporting heavy cargo that doesn’t take up much space. It’s ideal for materials like construction supplies, machinery, metals, or chemicals in barrels.

The 40-foot container is a better option for voluminous cargo. Its extended length allows for more pallets to be loaded, increasing logistics efficiency for large-scale deliveries. It is a popular choice in wholesale trade, for exporting industrial goods, textiles, or finished products.

Open-Sided Containers (OS)

This variation of the standard Dry Van container is equipped with full-length side doors on one of its walls. It allows easier access to the cargo and is ideal for transporting long items that would be difficult to load through standard doors — such as pipes, planks, or steel structures.

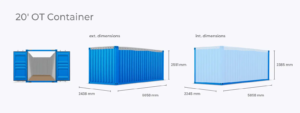

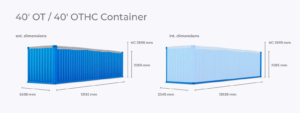

Open Top Containers (OT)

Open Top containers, while classified as standard containers, offer additional functionality — an open roof. They are used when goods require loading and unloading from above, for example with cranes. These containers are often used to transport machinery, infrastructure components, or bulk materials. Open Top containers are covered with a special tarpaulin during transport.

Hard Top Containers (HT)

This is a sturdier version of the open-top container. Instead of a tarpaulin, the Hard Top container has a removable steel roof, which provides increased protection for the cargo. It is often used for transporting tall goods or loads that require crane handling, while also needing better shielding from external conditions.

Refrigerated Containers (Reefer, RF)

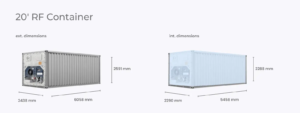

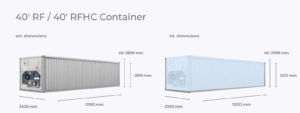

Refrigerated containers, also known as reefers, are designed for transporting goods that require a controlled, constant temperature. They are essential for the shipment of food products, pharmaceuticals, and certain chemicals. Thanks to built-in cooling systems and insulation, they maintain stable conditions — including temperature and humidity — throughout the entire shipping route.

Reefers come in several size variants. The 20-foot version is ideal for smaller shipments — such as fresh food, dairy, or pharmaceuticals. On the other hand, 40-foot containers are chosen for larger export loads like fruits, vegetables, or frozen meat. Additional vertical space is available in High Cube models (40′ RF HC), which are especially useful for stacking goods or when extra airflow space is needed between transported products.

Thermal Containers

Thermal containers are a lesser-known yet very useful solution for goods sensitive to temperature changes. Unlike refrigerated containers, they do not have an active cooling system but are equipped with a special insulating layer that helps maintain a stable internal temperature.

They are mainly used for transporting goods that do not require constant refrigeration but could be affected by temperature fluctuations — such as chocolate, dairy products, or cosmetics.

They are also a good choice for short-distance shipments, where running a full reefer container would simply be uneconomical.

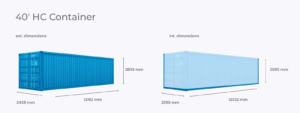

High Cube Containers (HC)

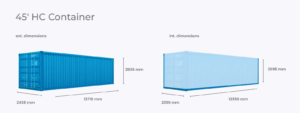

High Cube containers were created to transport goods that require additional vertical space. Although their length and width are the same as standard containers, their height is approximately 30 cm greater, resulting in significantly more capacity. They are an ideal solution for transporting bulky yet relatively lightweight goods, such as furniture, clothing, or industrial components.

The most commonly used model is the 40′ HC container, which allows for better space utilization, especially when goods are stacked. For even greater spatial needs, the 45′ HC container offers extra length and volume. The 45′ HC PW (Pallet Wide) version is specifically designed to maximize loading space for Euro pallets, which is particularly important in European transport operations.

Flat Rack Containers (FR)

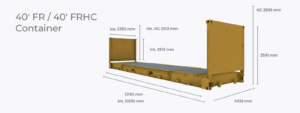

Flat Rack containers, also known as platform containers, are designed for transporting cargo that, due to its size, weight, or irregular shape, does not fit into standard shipping containers. They lack both a roof and side walls, which allows for easy loading from the top or the sides.

The 20′ Flat Rack is ideal for transporting industrial machines, engines, or steel components — especially over shorter distances. The larger 40′ Flat Rack is commonly used for exceptionally heavy or long cargo, such as steel structures, vehicles, or infrastructure components — particularly in the construction and energy sectors. Thanks to solid lashing points, it ensures secure immobilization of even the most demanding cargo.

However, due to their open design, Flat Racks require additional securing — such as straps, tarps, or protective elements — especially in intermodal transport.

Platform Containers

Platform containers are the most basic form of maritime container — consisting solely of a reinforced floor mounted within a steel frame. They have no side walls or roof, which provides maximum flexibility for loading and unloading oversized cargo.

They are widely used in transporting single-piece cargo that, due to its length, height, or weight, does not fit into other types of shipping containers — such as steel structures, turbines, or large transformers. The robust floor allows for secure fastening and supports significant point loads, making platform containers almost indispensable in heavy industry logistics.

20’ platforms are often chosen for smaller but extremely heavy components — their compact size allows for easier maneuvering in ports and at transshipment stations. Meanwhile, 40’ platforms are designed for large industrial projects where both load-bearing capacity and cargo length matter. Thanks to ISO compliance, platform containers can also be used in intermodal transport.

Tank Containers (TC)

Tank containers, also referred to as tankers or ISO tanks, are designed for the transport of liquids, gases, and chemicals. Their construction differs completely from traditional shipping containers — instead of a box-shaped interior, they feature a cylindrical tank mounted within a container frame.

Tanks provide a safe and efficient way to transport goods such as food-grade liquids, chemicals, fuels, or pressurized gases. Their airtight construction and built-in safety features minimize the risk of leaks and meet regulatory standards for the transportation of hazardous materials.

Depending on the type of cargo, tank containers are classified into three categories:

IMO 0 – Food-grade Products

These containers are intended for the transport of non-hazardous liquids such as milk, mineral water, vegetable oils, or wine. They maintain the highest hygiene standards and do not require any special safety markings.

IMO 1 – Hazardous substances

These are the most secure tank containers, used for transporting high-risk chemicals. They must be equipped with a top discharge system and feature additional reinforcements and safety mechanisms to prevent leaks or ignition.

IMO 2 – Medium-risk chemicals and protected food products

This type of container is used for transporting less aggressive chemicals as well as certain liquid food products (that carry some hazard classification). These cargoes require extra protection (e.g., from contamination) and can be handled via bottom discharge. Some IMO 2 containers are also equipped with electric heating systems.

Potable Liquids Only

This is a specialized version of the tank container used solely for transporting drinking water or food-grade beverages. It features an interior coating that is corrosion-resistant and chemically neutral. Materials used in construction meet strict sanitary standards.

Pallet Wide Containers (PW)

Pallet Wide containers are specifically designed to maximize cargo space when transporting Euro pallets. Thanks to a slightly wider internal dimension, these containers allow for loading more pallets without leaving empty spaces, resulting in higher efficiency and reduced transport costs.

The 40′ PW version can hold up to 30 Euro pallets, making it an ideal choice for intermodal transport and regional distribution. Meanwhile, the 45′ PW containers offer even more space, commonly used in port-to-warehouse logistics and groupage shipments. This is a popular solution in industries such as food and cosmetics.

Double Door Containers (DD)

Double Door containers feature two sets of doors — one on each of the shorter ends. This design enables faster loading and unloading of cargo, especially useful when the container is being repacked or accessed in tight spaces.

They are ideal for transporting long items or when fast unloading is crucial — for example, in construction, events, or vehicle logistics.

Double Door containers are usually available in 20′ and 40′ versions. They are also often modified, for example into mobile units, combining multiple functions in a single container.

Bulk Containers

Bulk containers are designed for transporting loose goods such as grain, granules, or pellets. Their most distinctive feature is the presence of special openings on the roof for top loading, along with discharge hatches at the bottom for easy gravity unloading.

Although they look like standard Dry Van containers from the outside, their interior is often adapted for transporting bulk materials — for instance, they may be lined with bags or special protective inserts. They are widely used in agriculture, the chemical and food industries, as well as in the logistics of recycled raw materials.

You might also be interested in: What are Incoterms? International commercial terms in practice >>>

Specialized Containers (Named Cargo Containers)

Some cargo types require specific transportation conditions. For them, specialized containers have been designed to meet particular needs.

Livestock Containers

Tego typu kontenery wyposażone są w wentylację, przegrody i poidła. Umożliwiają bezpieczny oraz humanitarny przewóz zwierząt, takich jak bydło, owce czy konie.

Car Transport Containers

Designed for transporting vehicles such as passenger cars and vans. These are often double-door containers, fitted with ramps or securing systems that enable safe and easy loading and unloading.

Ventilated Containers

Among the more important types of containers used in maritime transport are ventilated containers. These are modified versions of standard containers, equipped with ventilation openings that allow passive air circulation. They are indispensable for goods sensitive to moisture and mold. This solution protects cargo from humidity and condensation, while maintaining structural tightness.

Ventilated containers are ideal for transporting coffee, cocoa, tobacco, seeds, textiles, wood, and paper.

Summary

Maritime container transport plays a crucial role in international freight thanks to the standardization of container dimensions. This standardization allows for their efficient use in both multimodal and intermodal transport—without the need for reloading between transport modes.

Choosing the right container goes far beyond technical specs—it’s a strategic decision that affects the safety, cost, and punctuality of deliveries. Each cargo type has its own specific requirements: some need constant temperature, others require special securing systems or unique loading access.

The variety of container types in maritime transport is a direct response to these needs. While standard containers are suitable for most general cargo, transporting refrigerated, hazardous, oversized, or bulk goods requires specialized technical solutions. Therefore, the choice of container should always be consulted with an experienced logistics operator. This ensures not only supply chain optimization but is also a real investment in safety, efficiency, and the reliable delivery of goods to their final destination.

Frequently Asked Questions (FAQ)

How are sea containers classified?

Containers used in maritime freight are classified by their purpose (e.g., standard, refrigerated, tank), size (20’, 40’, 45’), and construction (e.g., high cube, pallet wide, double door).

How many meters long is a shipping container?

A standard 20’ shipping container is approximately 6 meters long, while a 40’ container is about 12 meters. The typical width is around 2.44 meters, and the height is 2.59 meters for Dry Vans (DV) and 2.90 meters for High Cube (HC) containers.

What’s the difference between a 40′ DV and a 40′ HC container?

The difference lies in height. A 40′ HC (High Cube) container is 1 foot (about 30 cm) taller than a standard 40′ DV (Dry Van), offering greater cargo volume. The tare weight of the 40′ HC container is also typically higher.